Moisture Resistant MgO Heat Dissipation Fillers

Process for Suppression of MgO Filler Hydration & Its Advantage

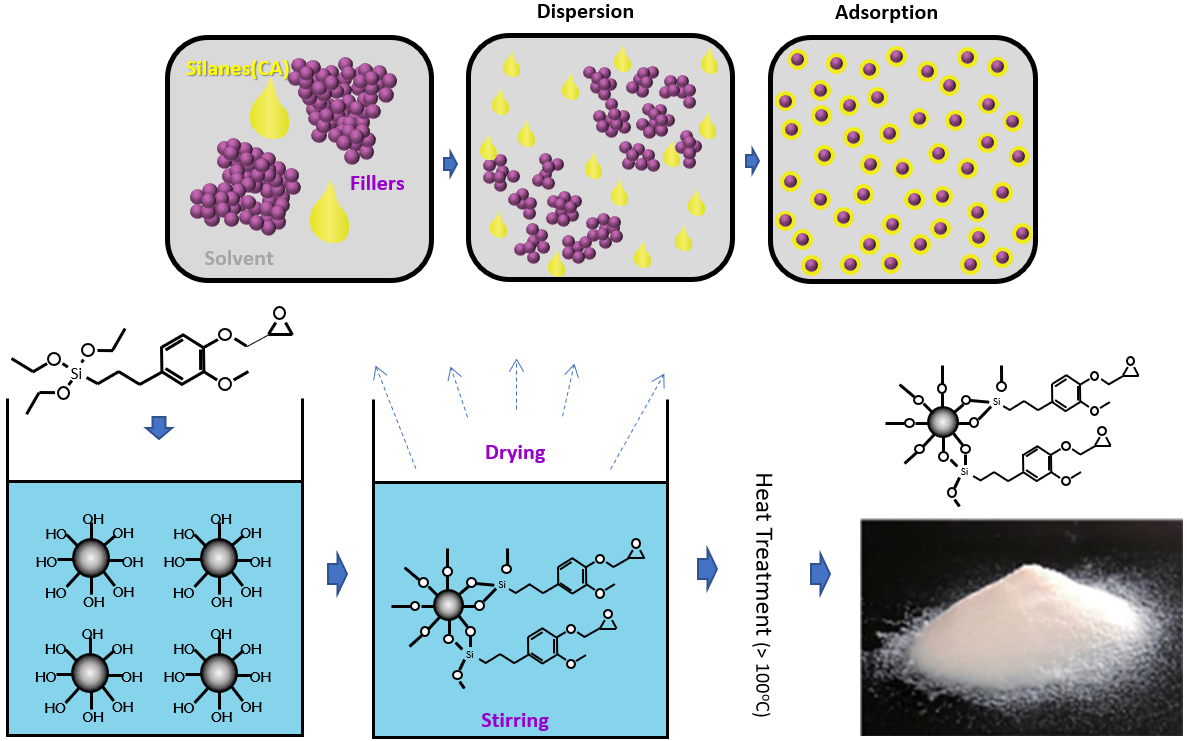

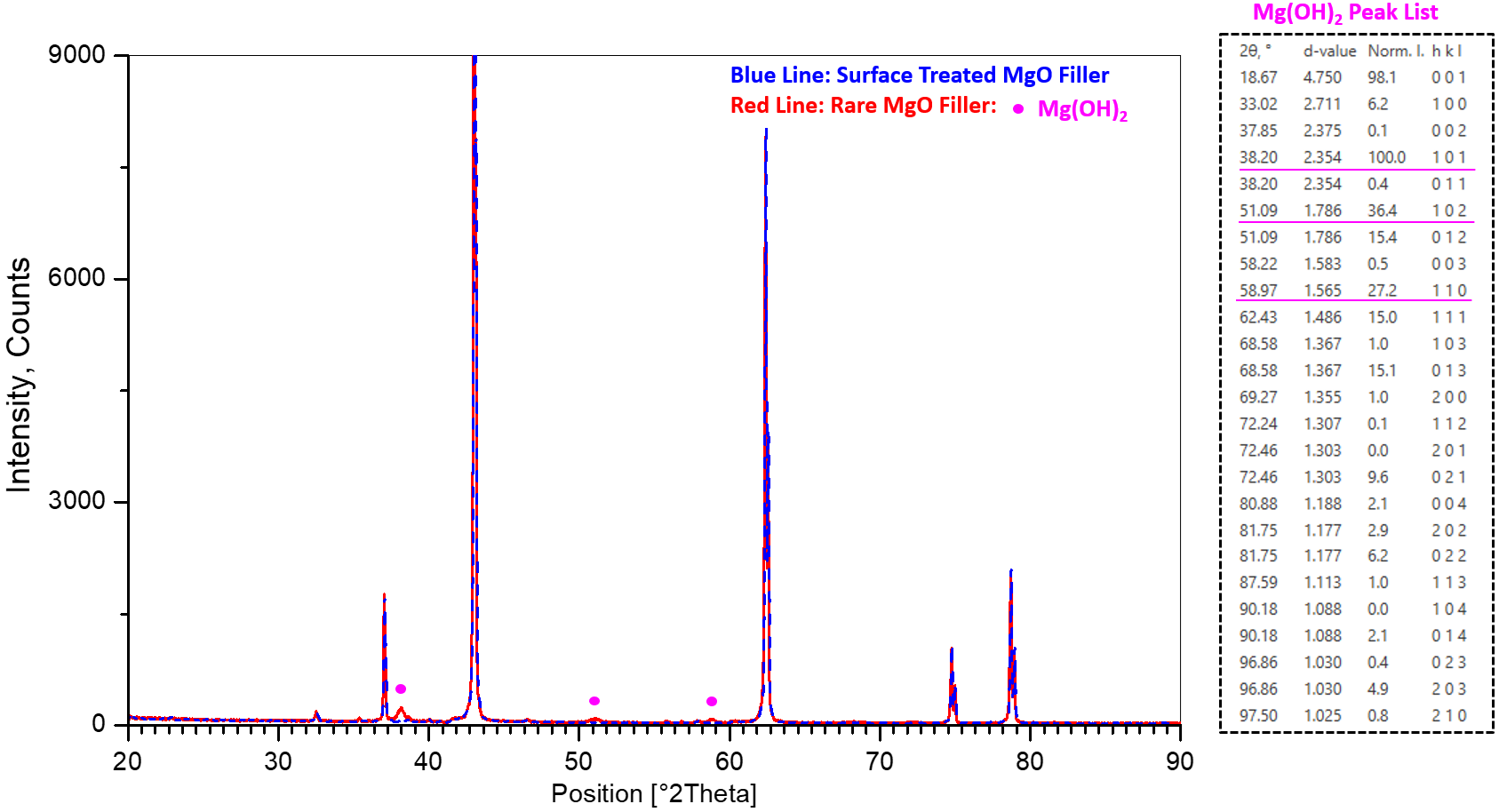

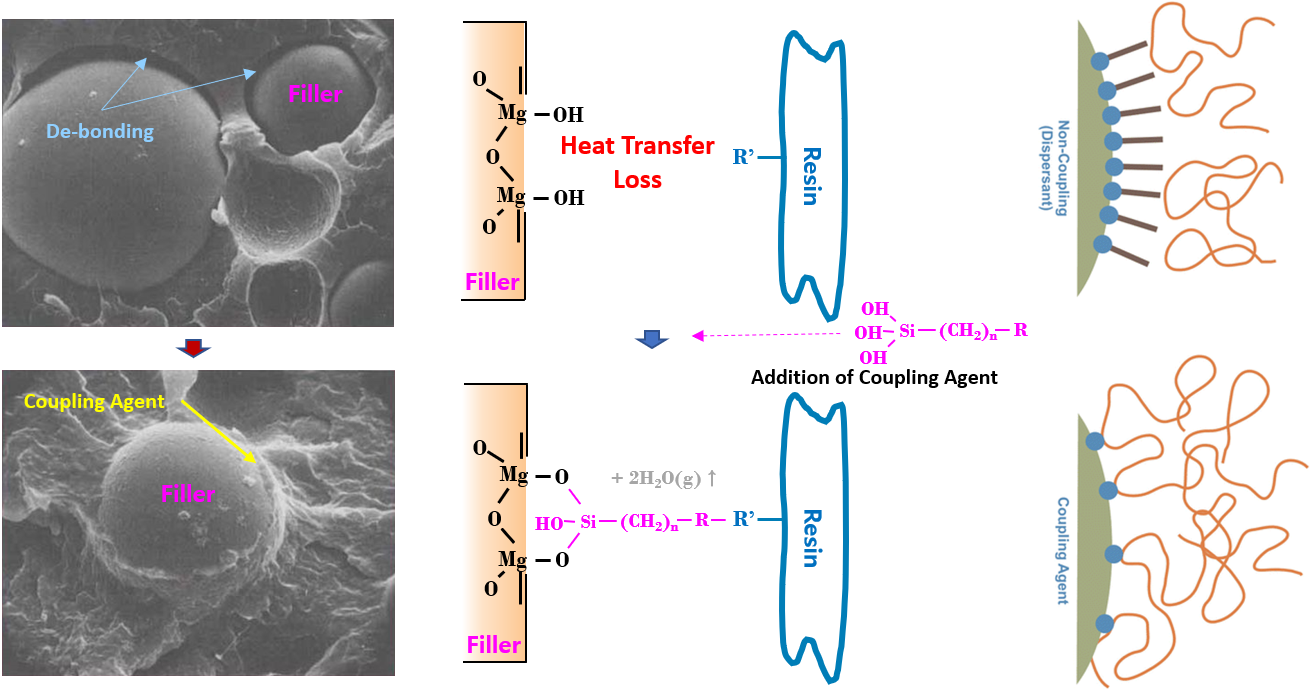

(1) Surface Treatment of MgO Fillers

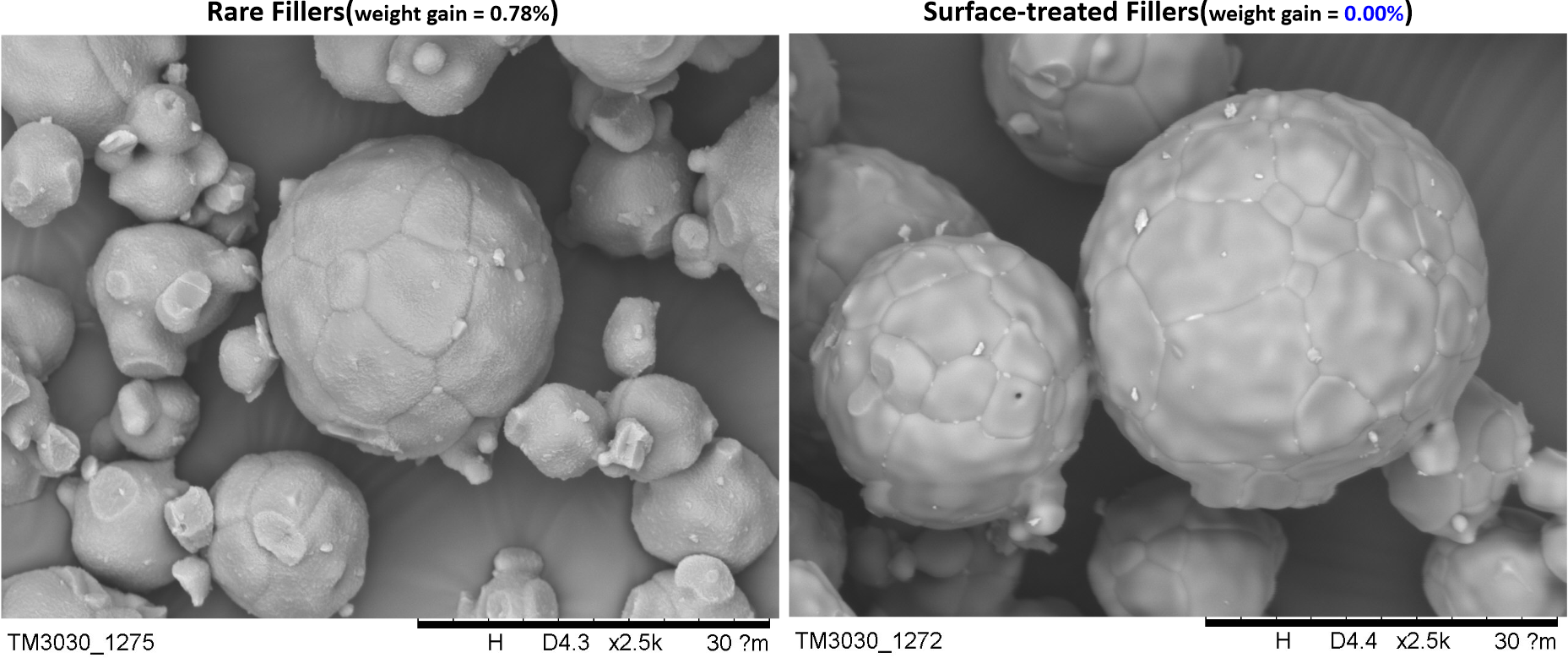

(2) Test for Moisture Resistance: After 85oC/85% for 72h Humidity Test

(3) Advantage of Surface Treatment for MgO Fillers

Surface treatment not only improves the moisture resistance of the magnesium oxide heat dissipation filler, but also has the advantage of facilitating heat transfer by strengthening the bond between the filler surface and the resin in TIM. Furthermore, as the heat dissipation fillers come to be reduced in their size, they stick together during sintering, and thus a large amount of rare surfaces are exposed during the process of separating them, so surface treatment is an unavoidable process.

--------------------------------------------------------------------------------------------------------------------------------

[Comparative Examples]

--------------------------------------------------------------------------------------------------------------------------------

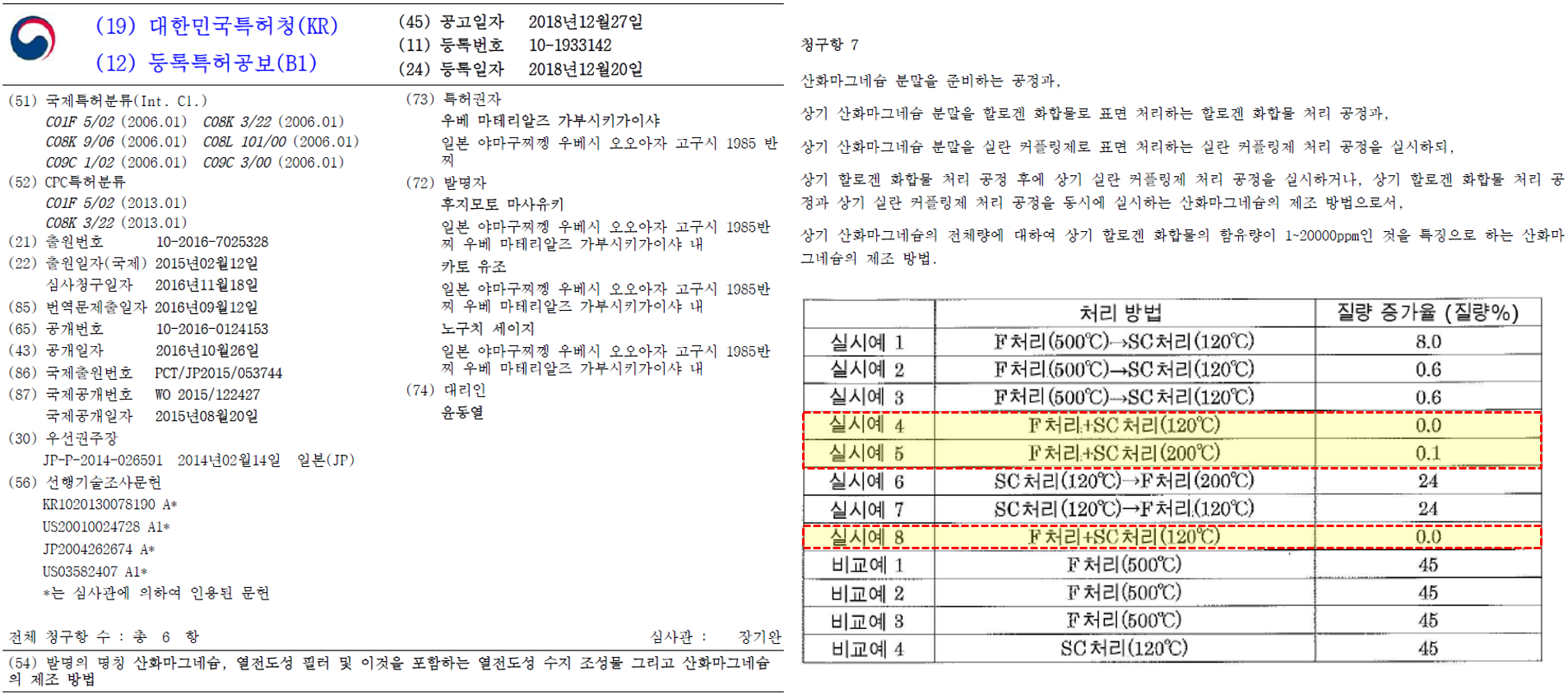

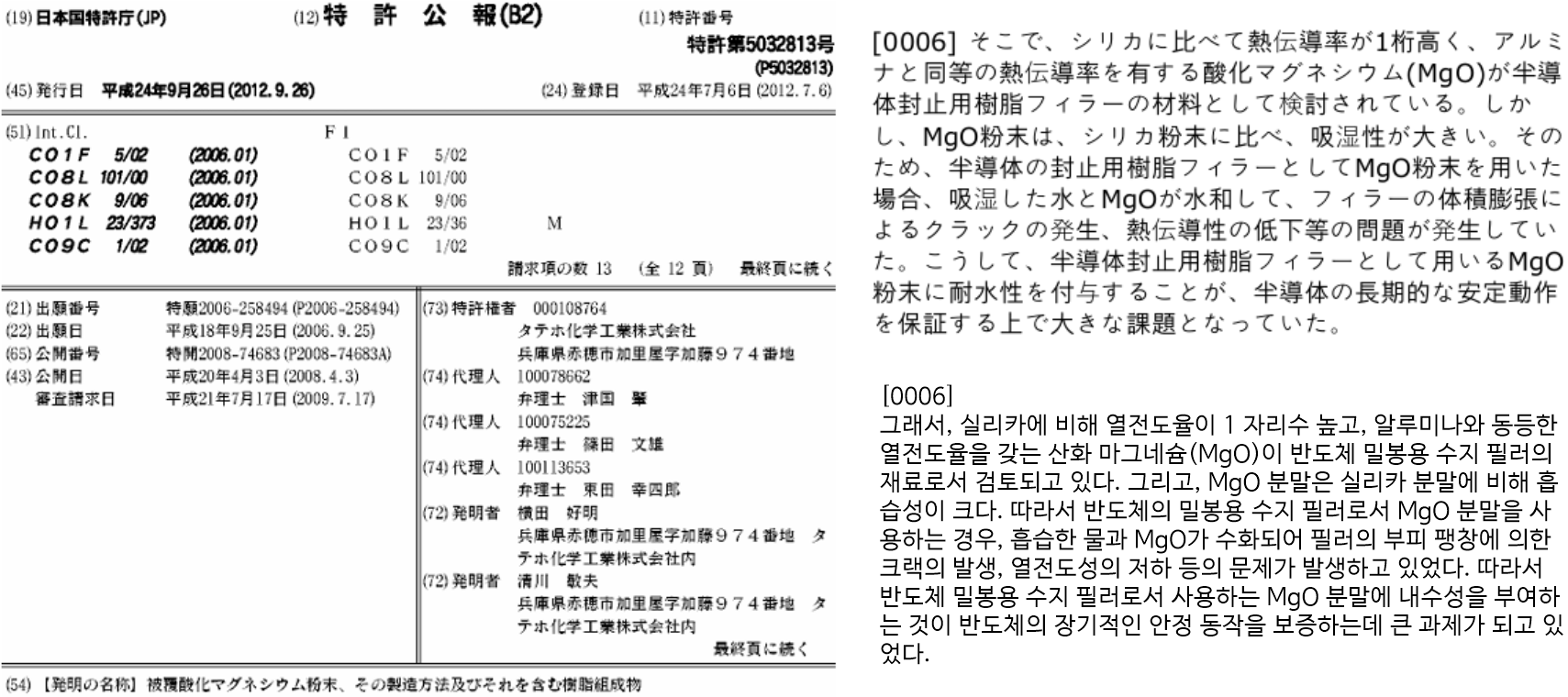

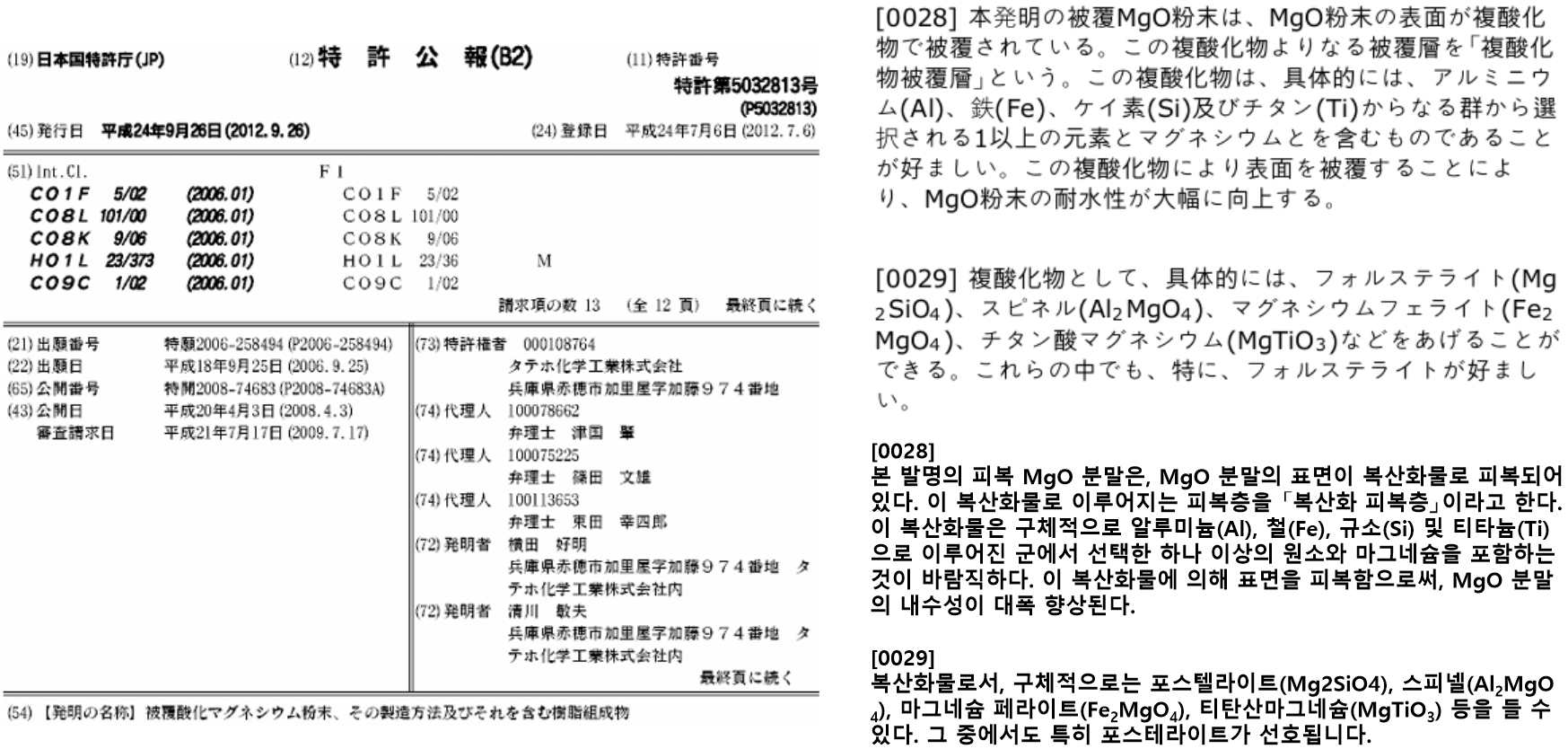

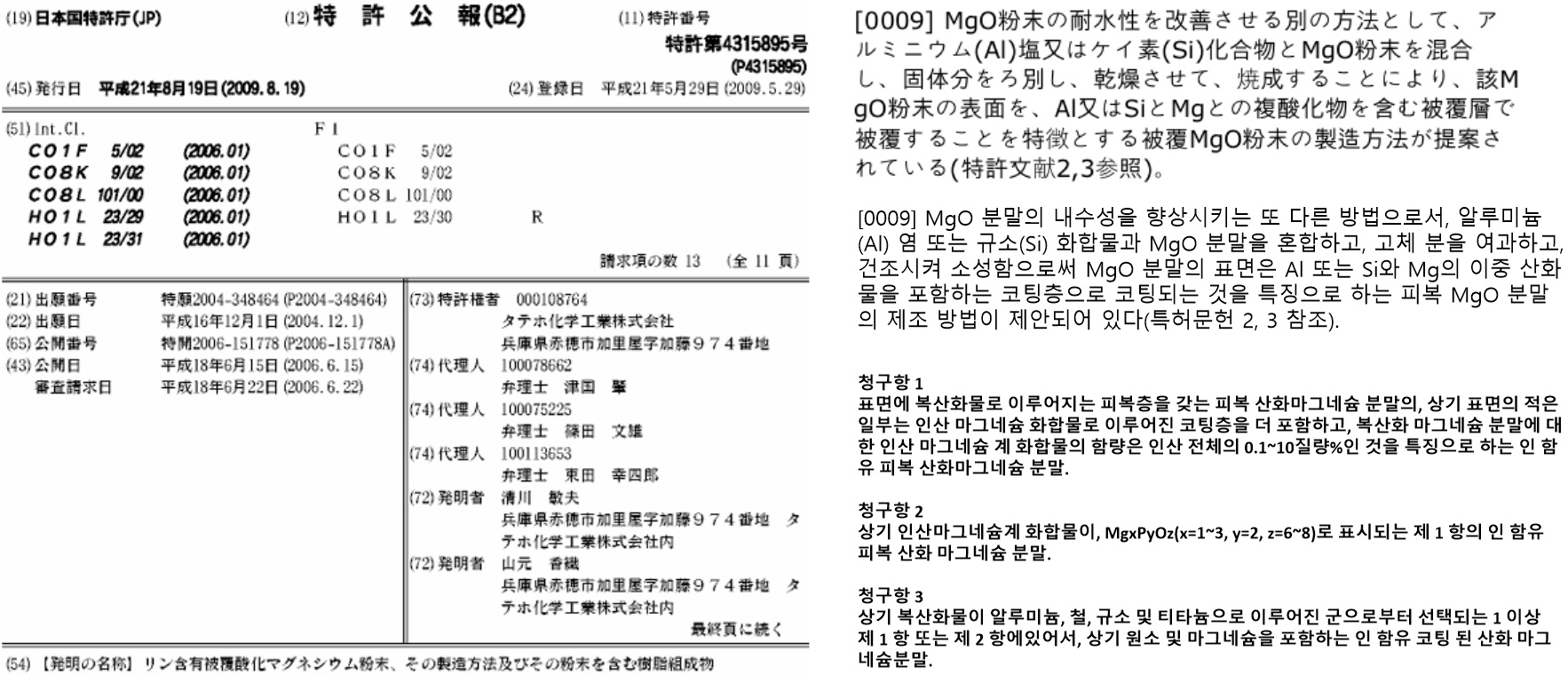

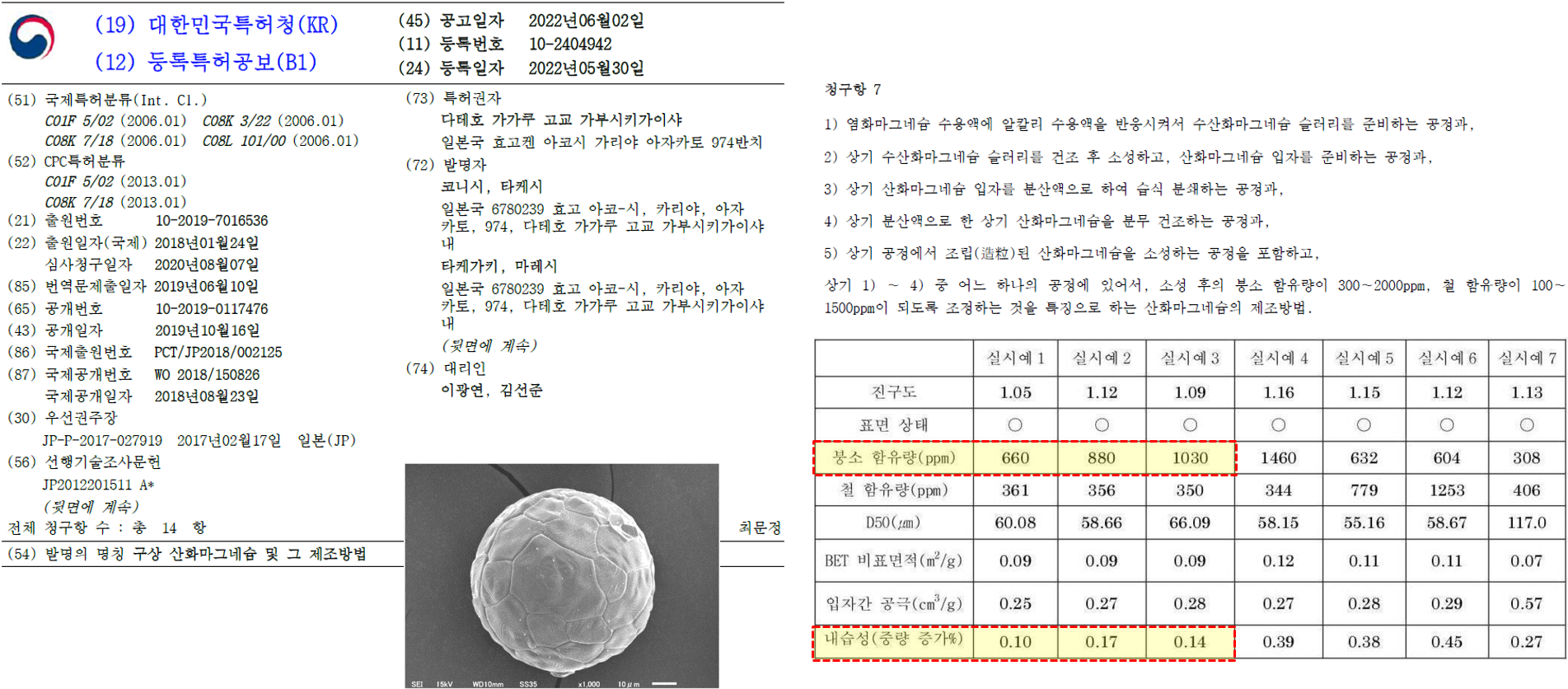

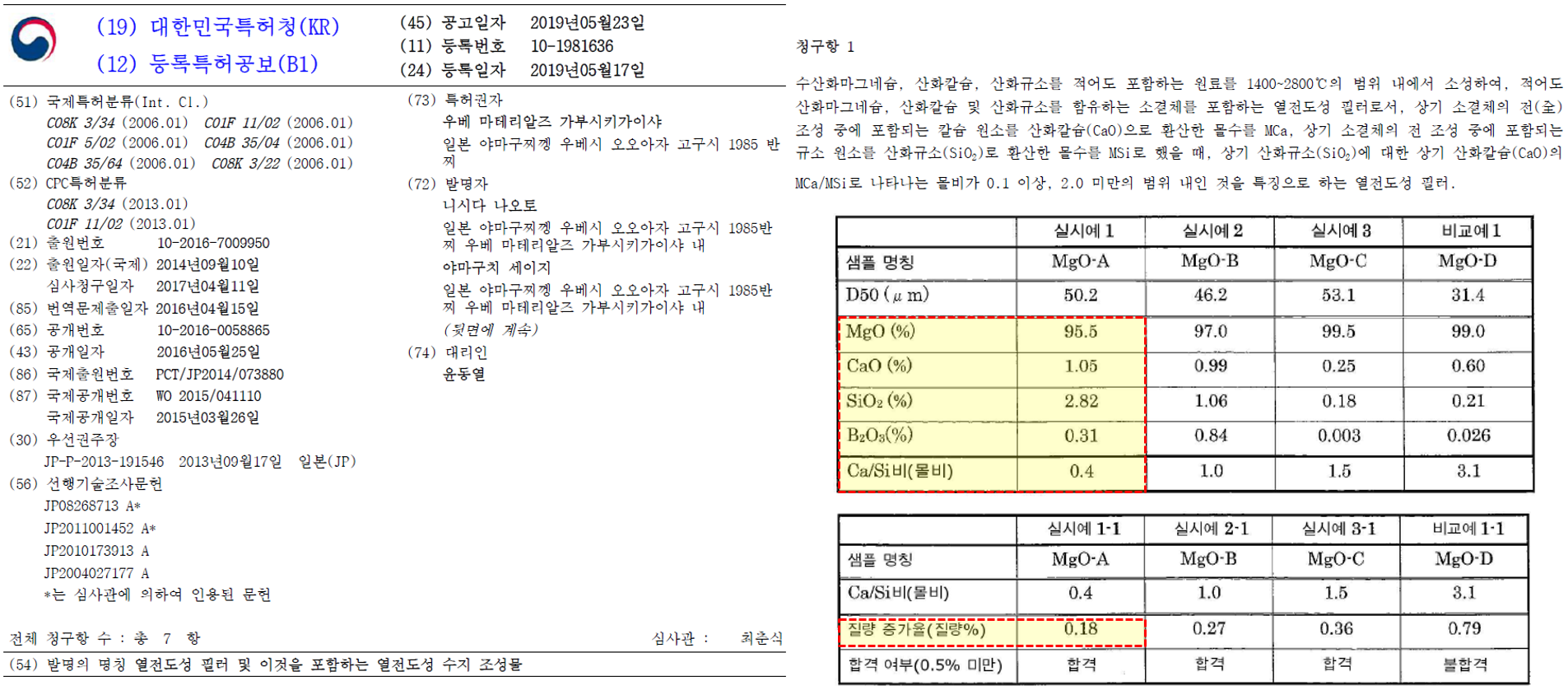

(1) Method A: Formation of a Protective (oxide) Layer on MgO Filler

(1)-1 :

(1)-2 :

(1)-3

(1)-4

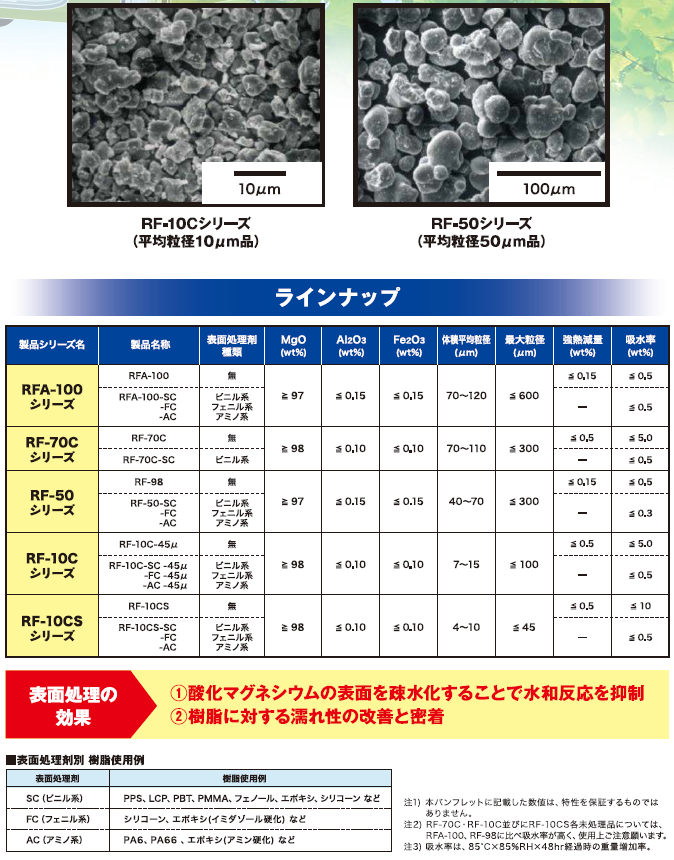

(2) Method B: Surface Treatment for Providing Hydrophobicity onto MgO Filler Surface