High Strength Porous Spherical Fillers

Development of Composite Fillers

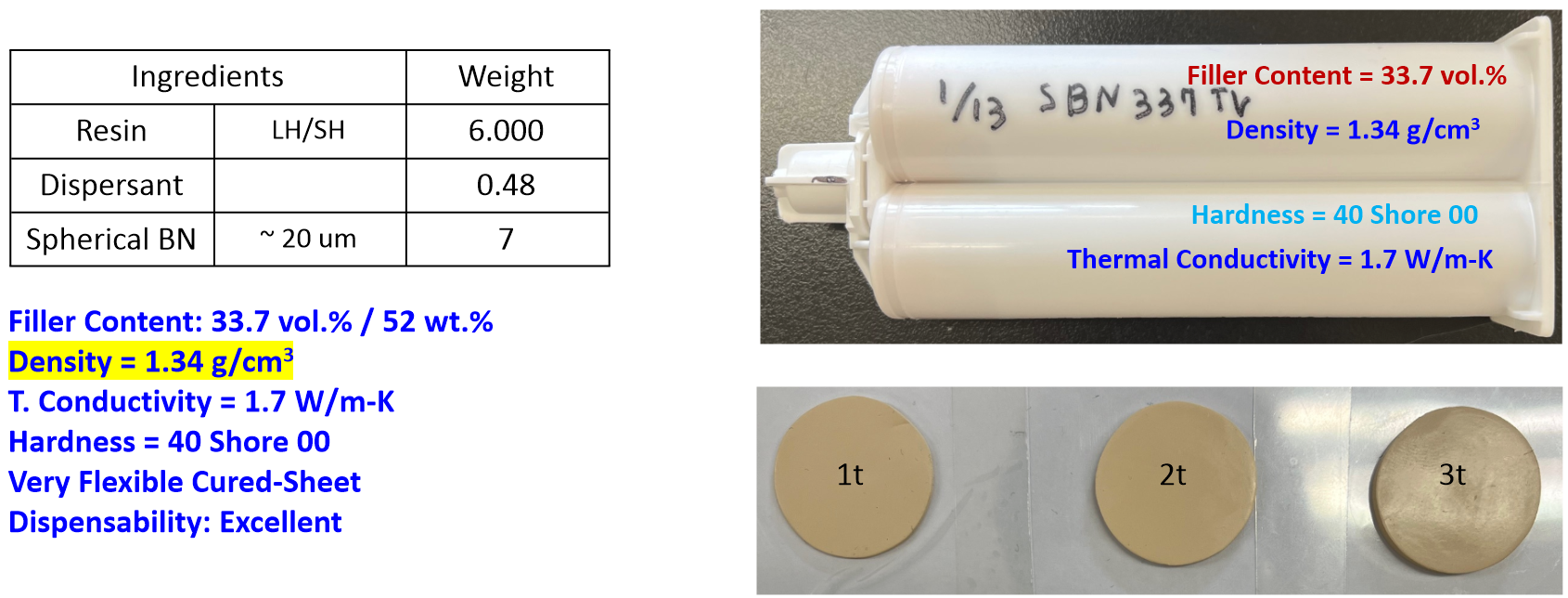

| Made by Yeungnam University | hexagonal Boron Nitride | Aluminum Nitride | BN-AlN Composite |

| Primary Particle | 70% <0.5 um + 30% 10 um | 70% 0.5 um + 30% 2.7 um | 70% AlN 0.5um+30% BN 10um |

| Manufacuring Process* | Aqueous BN suspension | Aqueous AlN suspension | Aqueous BN/AlN suspension |

| Solid Loading in Suspension | > 20 vol.% | > 31 vol.% | > 30 vol.% |

| Avg. Granule Size | ~ 20 um | ~ 20 um | ~20 um |

| Max. Dispensable Filler Content | ~ 52 wt.% (33.7 vol.%) | ~ 78.4 wt.% (52.2 vol.%) | In development |

| Specific Gravity | 1.35 g/cm3 | 2.17g/cm3 | " |

|

T. Conductivity (Non-sintered Porous Filler) |

1.7 W/m-K | 1.8 W/m-K | " |

|

T. Conductivity (Sintered Dense Filler) |

- | In development | " |

*) Kor. Pat. Application 10-2024-0197846

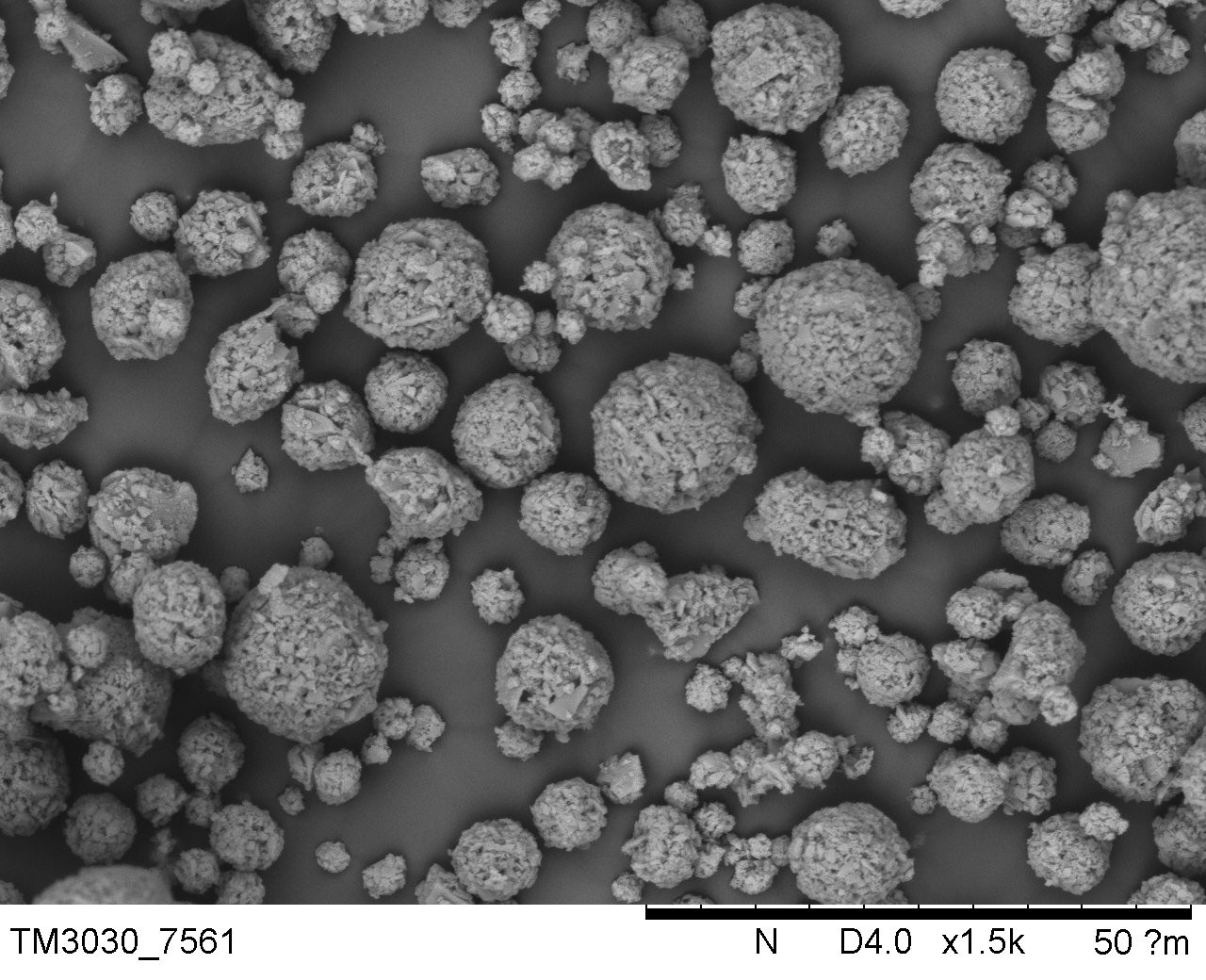

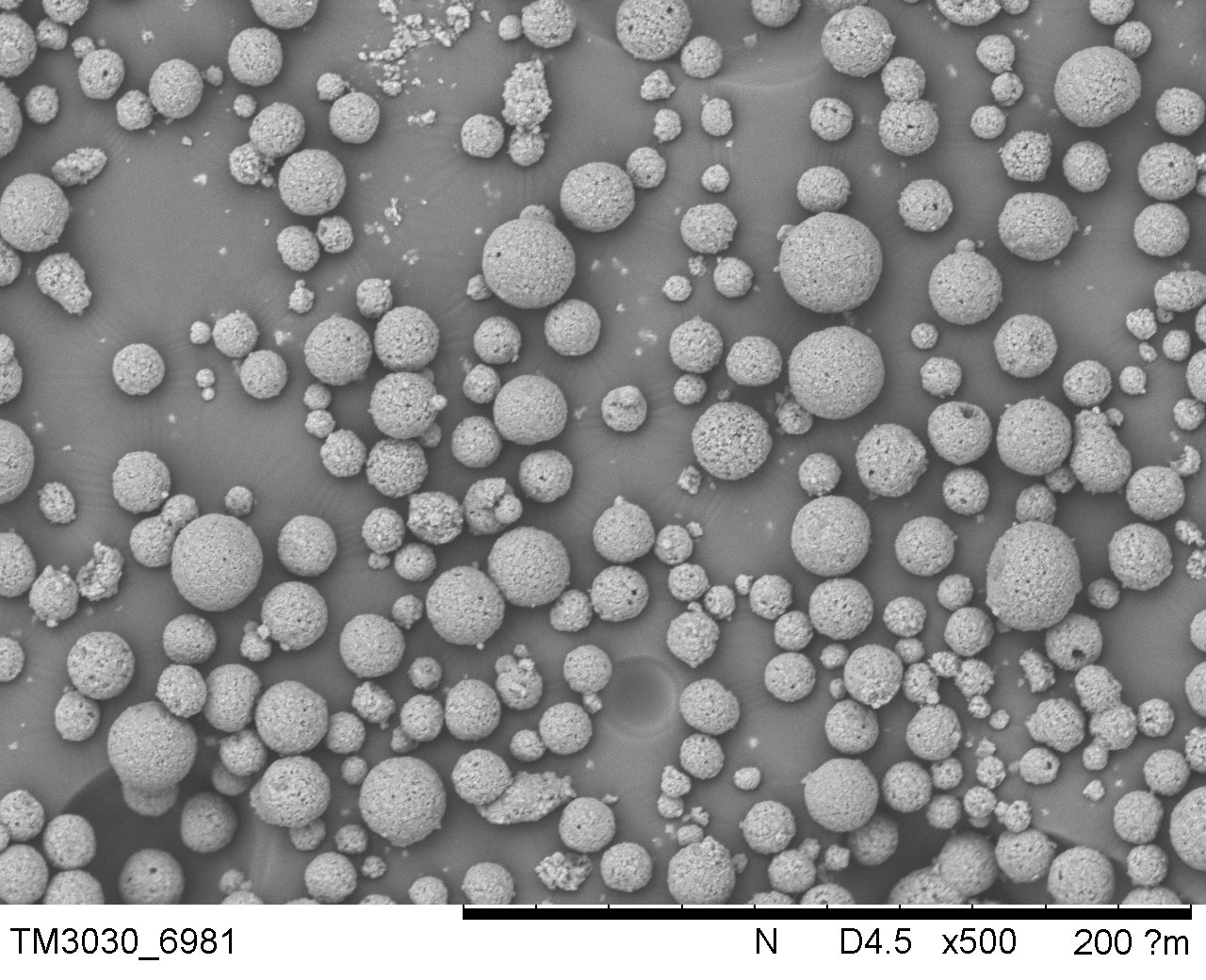

(1-1) Spherical h-BN Fillers

(1-2) Gap-filler TIM using the above BN fillers

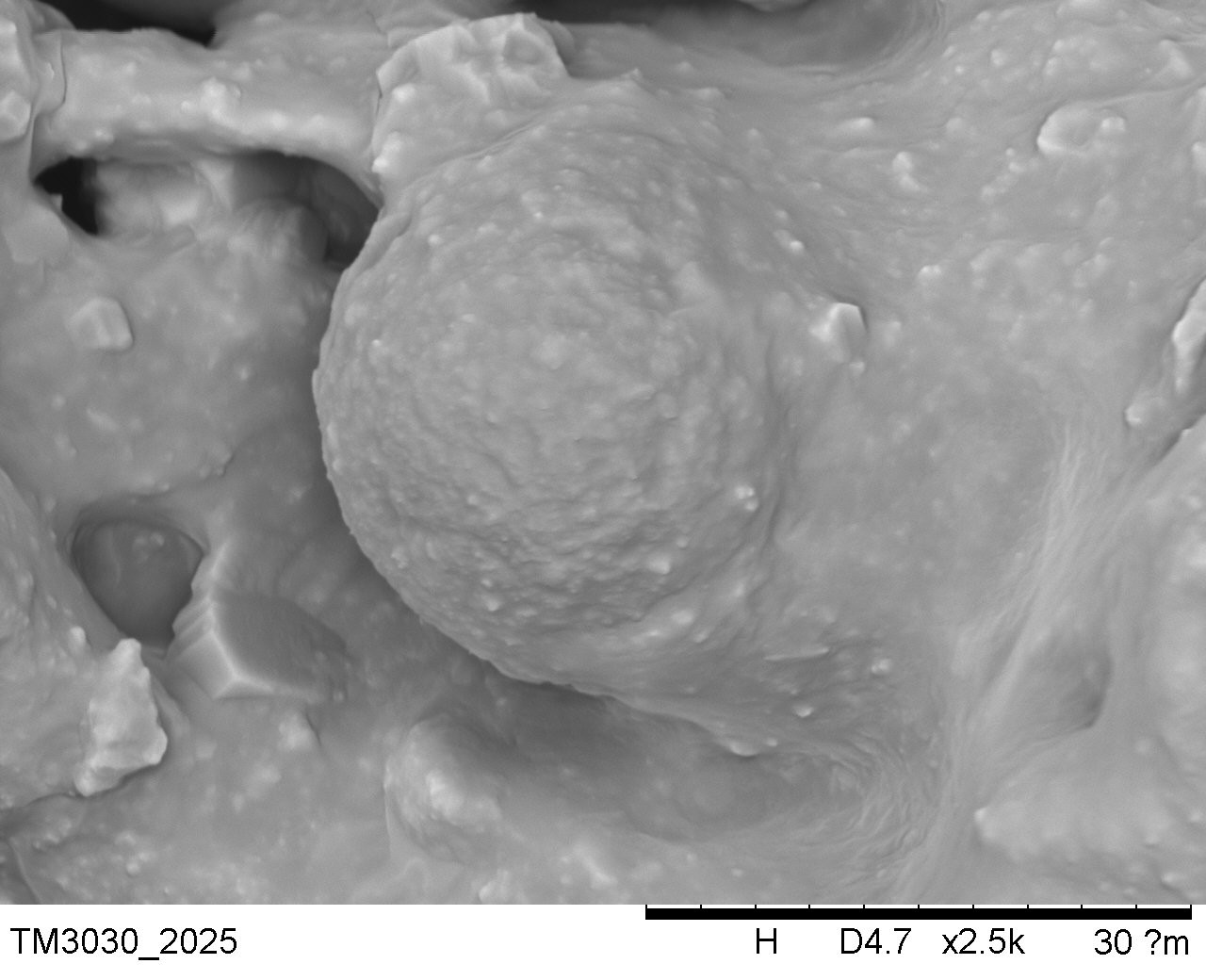

Note that the central spherical particle above in the gap-filler TIM is the prepared BN filler particle

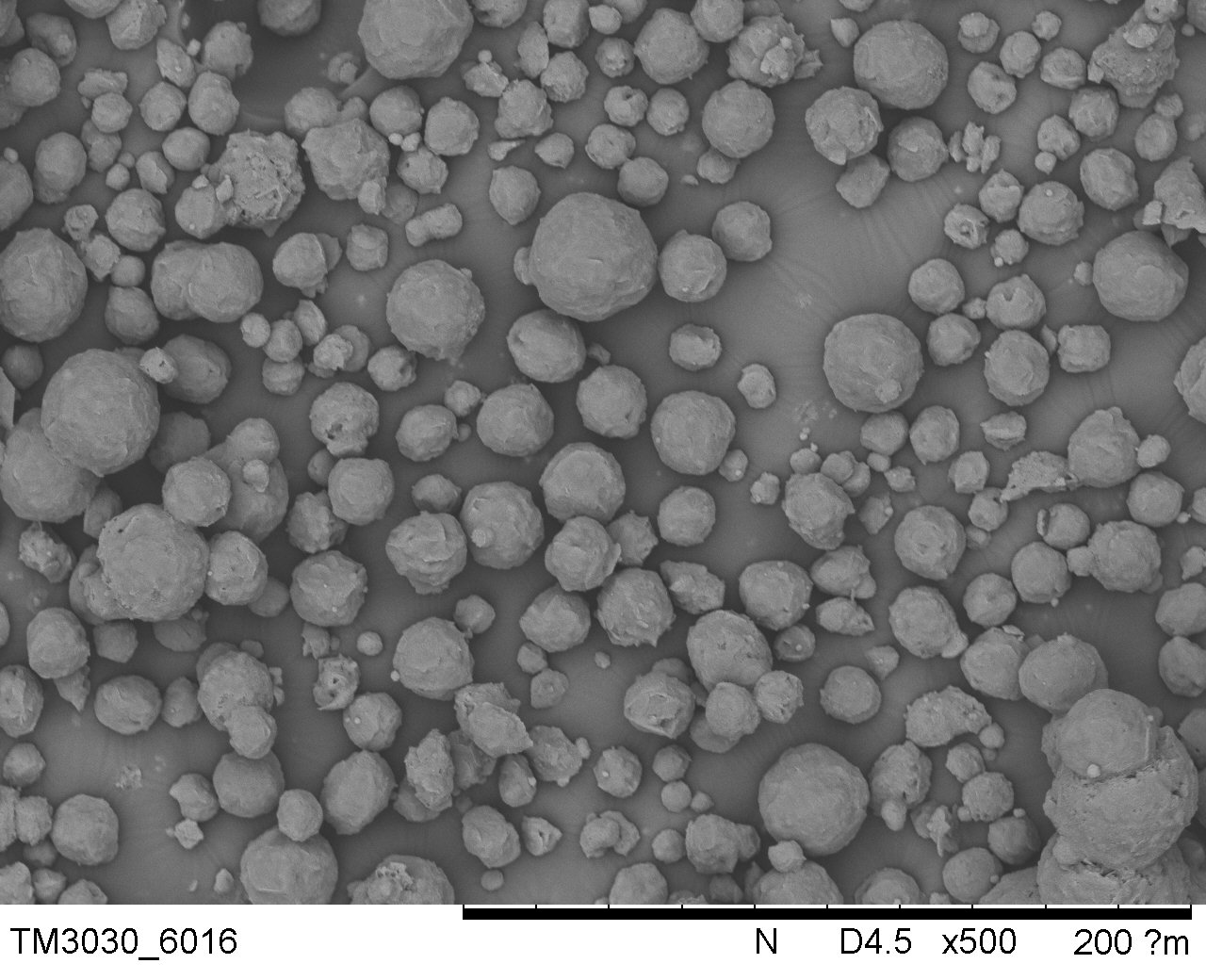

(2) Spherical AlN Fillers

| Made by Yeungnam University | BN/MgO | AlN/MgO | Silicon Carbide |

| Primary Particle |

30% BN 10 um 70% MgO 0.5um |

30% AlN 2.7 um 70% MgO 0.5 um |

~ 70% 2.4 um + 30% 0.5 um |

| Manufacuring Process* | Aq. BN/MgO suspension | Aq. AlN/MgO suspension | Aq. SiC suspension |

| Solid Loading in Suspension | > 20 vol.% | > 31 vol.% | > 20 vol.% |

| Avg. Granule Size | ~ 20 um | ~ 20 um | ~20 um |

| Max. Dispensable Filler Content | - | - | - |

| Specific Gravity | - | - | - |

|

T. Conductivity (Non-sintered Porous Filler) |

- | - | - |

|

T. Conductivity (Sintered Dense Filler) |

- | - | - |

*) Kor. Pat. Application 10-2024-0197846

(3) Spherical SiC Fillers